SPICESKATE® | OKTOSURF

ENGINEERED FOR SURF

Introducing the all-new OKTOSURF, the second generation of SpiceSkate® OKTO System that takes performance to new heights.

OKTOSURF beautifully mimics the fluid and dynamic movements of surfing. With the system, you can practice your surf skills on land, carefully maneuvering deeper and more dynamic turns, which is great for when you can't get to the ocean.

OKTOSURF’s distinctive advantage helps riders achieve even higher speeds and greater agility to navigate tight turns and carve through crowded areas. A truly unique experience that always keeps your skating routine fresh and exciting! It may even inspire you to invent new tricks and techniques.

REACTS TO YOU AND YOUR CONCRETE

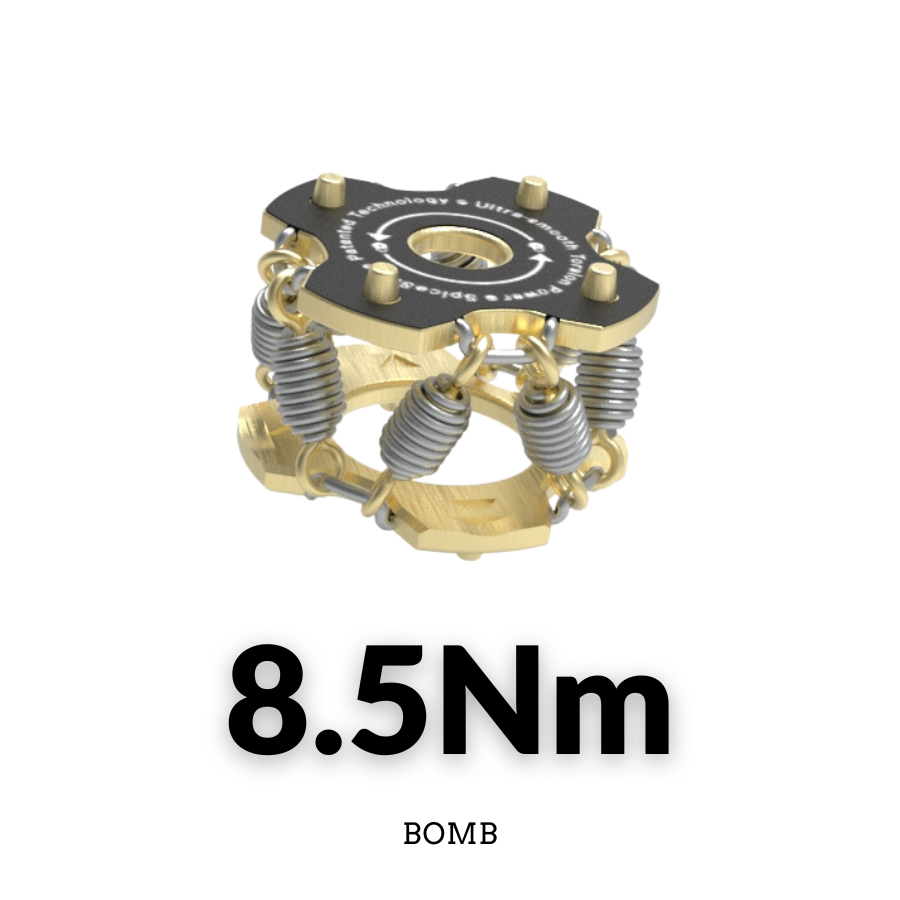

The patented innovative Capsule as a whole dictates the massive release of Torsion Power, while the tension springs within intelligently distribute the energy to ensure optimum responsiveness and smoothness.

CUTTING-EDGE AIR VIBRATION CANCELING

Inside the OKTOSURF Capsule, there are eight U-Shaped vibration-canceling anchors that immaculately manage the multi-dimensional frictions generated by tension springs, canceling the internal vibration in carve and turn.

PLUG & SURF

PLUG & SURF The ingenious design of the Capsule Stabilizer makes the swapping and installation of capsules exceptionally easy and intuitive, which empowers riders to experience different levels of land-based surfing, anytime, anywhere – hassle free. SpiceSkate® is delighted and proud to be honored with the Red Dot Design Award [2022]. It is one thing to come up with great ideas for a surfskate system, but a totally different thing to design, test and implement it. The R & D has spent endless hours in the lab where they successfully invented the state-of-the-art SpiceSkate® OKTO System. With long stretches of effort, the crew build perseverance and foster new creativity striving to become the innovators that can truly bring revolutionary products into the world.

OKTOSURF Series

The R & D team spent endless hours in the lab to have successfully invented the state-of-the-art SpiceSkate® OKTO System which won the Red Dot Design Award [2022]. OKTOSURF is OKTO’s second generation that offers Capsule with even higher torsion power.

- CAPSULE BOMB for OKTOSURF: 8.5 Nm

- CAPSULE Double-Up for OKTO: 6.8 Nm

The major difference between them is the way torsion force is generated. Spice Pilot uses 1 Torsion Spring while OKTO / OKTOSURF has a capsule that is composed of 8 tension springs. Both systems are good for all-round skating. With that said, some skaters prefer quick and hard rebounds for each pump (Spice Pilot) while others like more smooth but strong rebounds (OKTO / OKTOSURF).

Aluminum Alloy A356.2-T6 is a specific type of aluminum alloy. The A356 alloy is a commonly used aluminum-silicon alloy that enhances its properties. The "2" in A356.2 indicates a variation of the basic A356 alloy composition. The T6 temper is a specific heat treatment applied to the aluminum alloy. This process enhances the alloy's strength while maintaining a significant level of toughness for hard impact. The T6 temper results in much improved mechanical properties, making the material ideal for SpiceSkate OKTO System.

Gravity die casting Technology, also known as permanent mold casting or gravity casting, is a casting process used to produce high-quality metal parts by pouring molten metal into a reusable metallic mold under the force of gravity. The mold is designed to withstand the high temperatures and pressures involved in the casting process. The technology produces SpiceSkate Adapter with marvelous surface finish and dimensional accuracy. The controlled cooling in the mold helps to promote uniform solidification and finer grain structure, resulting in improved mechanical properties of the cast parts. This makes gravity die casting great for producing SpiceSkate Adapter with ultra-high strength and excellent fatigue resistance.

Austenitic stainless steel grade 304 is a widely used stainless steel alloy known for its excellent corrosion resistance, high strength, and versatility. When combined with investment casting technology, which is a precision casting process, it offers the following benefits for the production of SpiceSkate OKTO Capsule:

- Corrosion Resistance: Grade 304 stainless steel is highly resistant to corrosion and oxidation in various environments, including acidic, alkaline, and chloride-containing solutions.

- Design Flexibility: Investment casting, also known as lost-wax casting, allows for the production of the Capsule’s intricate and complex shapes that are challenging to achieve with traditional manufacturing methods. This process enables the creation of detailed and near-net-shape parts of the capsule, reducing the need for subsequent machining operations.

- Superior Surface Finish: Investment casting results in parts with excellent surface finish and dimensional accuracy. The use of high-quality molds and precise control over the casting process ensures smooth and visually appealing surfaces, minimizing the need for additional surface treatments or finishing.

- Thin Wall Capability: Investment casting is well-suited for producing parts with thin walls and fine features of the OKTO Capsule. The process enables the creation of the thin sections and intricate geometries while maintaining structural integrity. This is particularly advantageous for OKTO Capsule where lightweight components are desired without compromising its strength.

- Material Integrity: Investment casting allows for precise control over the casting process, including solidification and cooling rates. This results in a fine-grained microstructure and improved material integrity, leading to enhanced mechanical properties, such as high tensile strength, good ductility, and impact resistance.

Austenitic stainless steel Grade 304, often referred to simply as 304 stainless steel, is one of the most widely used and versatile stainless steel grades. It belongs to the austenitic family of stainless steels, which are characterized by their high levels of chromium and nickel content. It exhibits excellent corrosion resistance and is known for its durability and strength. Grade 304 has good heat resistance that can withstand temperatures up to 870°C (1598°F) without significant loss of strength.